Discover our new image film:

Everything is possible

INDIVIDUALITY IS OUR STRENGTH

Whether calibrating, washing and drying, weighing, filling or sealing, we always guarantee a perfect result.

Upmann Verpackungsmaschinen GmbH manufactures machines in series and individual production. This enables us to respond to the respective customer requirements individually and to implement them optimally. Over 200 years of tradition and an award with the "Prof. Adalbert Seyfritz Prize" for exemplary technology transfer are only two important successes of our company.

We combine our experience with the latest technology so that you benefit.

Upmann foodtec was founded in 2013 to optimally supply the food industry with machines. At the same time, more and more non-food companies are relying on our company, because with our modern machines you can always process your products skilfully and precisely.

Services

What we do

Careful and professional planning is the basis for our successful work. Planning begins with a thorough assessment of the current situation. All relevant facts are analysed, solutions are developed and agreed with the customer. All our machines can be converted in their function without the use of tools.

Accept

We offer a wide range of different machines and systems for gentle and effective reception and processing of your products.

Ensure your product quality already during the acceptance process.

Processing & Sorting

For the preparation of foodstuffs, Upmann provides machines for goods reception as well as enterers, drum washers, roller dryers and sieve chain sorters.

The SORTOP sorter for carrots and potatoes sorts, calibrates and weighs with the best efficiency on the market.

Storage

Our fully automatic systems for space-saving storage and retrieval of crates. With integrated traceability of all product batches across the entire line and feeding of different packaging lines via an orbiter and a hopper system.

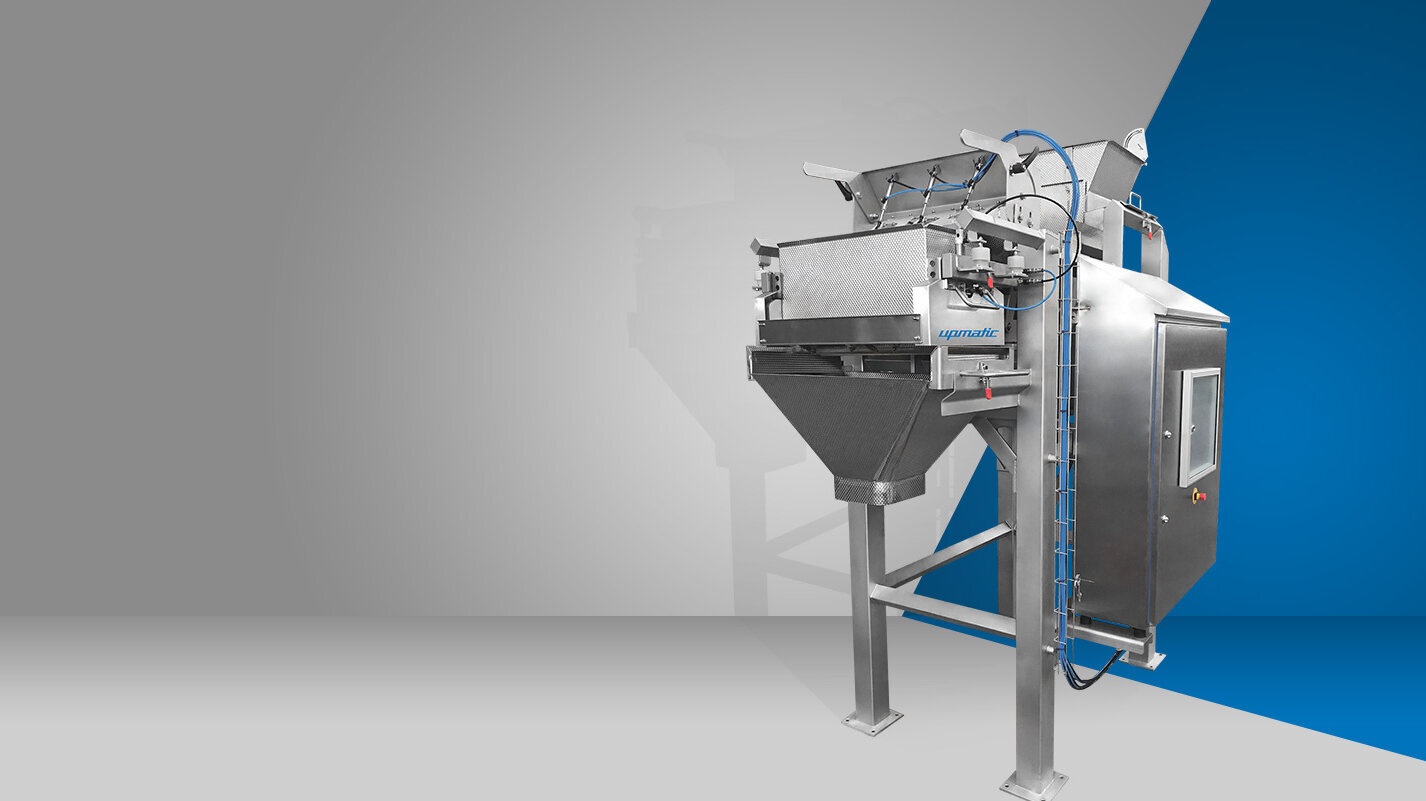

Weighing & Counting

Accurate counting is carried out by our electronic counting machines for coarse goods.

Precise weighing is always possible with our computer-controlled partial quantity and individual weighing machines for small and coarse goods, as well as our combination scales with weighing and counting technology. A scale has 7 - 15 output channels from which the partial quantities are fed out.

Packaging

For optimal packaging, we offer fully automatic filling and sealing machines that optionally fill your products into nets, trays, boxes, carry-fresh bags as well as paper bags and foil bags and seal them.

Insertion and repackaging

Inserting and repackaging is the final step in our product processing. Here, case packers fill crates, boxes or cartons with the packed goods.

Now the products are ready for delivery.

Latest News

Article in Freshplaza magazine

04.02.2021

Corona has significantly accelerated automation

In recent years, the agricultural industry has rapidly automated. Whether in sorting, preparation, weighing or packaging, fully automated solutions are increasingly being used. The purpose of this automation is to save staff and thus labor costs. This demand has only increased because of the current Corona requirements - such as distance rules and mouth and nose protection, observes Oliver Werner - Sales Manager Germany of the machinery and equipment group Upmann.

Active worldwide

We are active in many countries worldwide with 30 foreign representatives (e.g. Chile, Russia, Belarus, Hungary, Netherlands, South Africa).