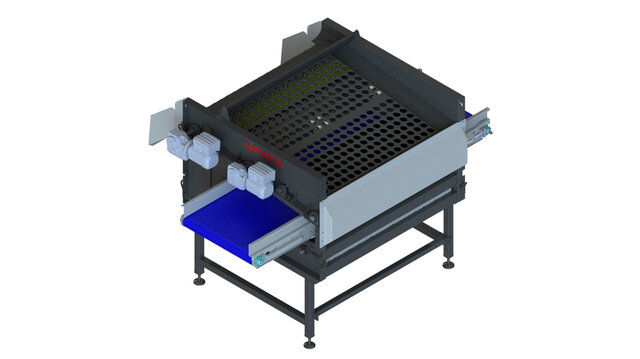

Upmatic chain sorter TYPE KS-1200-1800

Make two out of one!

The product is fed in via the infeed chute. The double jogging device distributes the product over the entire screen surface and gently turns it for sorting. Before the transfer roller, the product is lifted out of the sieve meshes by means of rubber stars and slides over a rubberised chute onto the next sieve or discharge conveyor.

The nylon plates on the sides protect against wear from soil and stones. To change the screen, the roller swing arm is relieved, the chain catch opened, the chain removed and rolled up. Winding up is done in reverse order.

Fields of application

Products to be processed